My Card

- NameEvan White

- BirthdayJuly 1982

- AddressVancouver, WA, United States

- Phone+1 (607) 301 0201

- Emailkindasimple@gmail.com

- Websitekindasimplesolutions.com

My Skills

Productive Languages

- C#

- JavaScript

Familiar Languages

- SQL

- VB

- JAVA

- Python

- PHP

- R

Platforms

- Microsoft Store

- Cordova

- Node.js

- Android

- iOS

Javascript Frameworks

- Backbone.js

- jQuery

- React.js

User Interface

- XAML

- HTML/CSS

Tooling

- Git

- Visual Studio

- Jenkins CI

- MSBuild

- Gulp, Webpack

- Bash

Database

- SQL Server

- Microsoft Access

About Me

Hi, My name is Evan

I have working in native mobile development space writing javascript and .NET applications. I have been a developer at Microsoft shops for 12 years being a generalist across the web and mobile stack. I'm motivated to use best practices, collaborate, and improve.

Employment

Mobile Developer2014 - Present

Mocaworks, LLC

Developing cross-platform Javascript/HTML5 Cordova application for mobile access to learning management service.

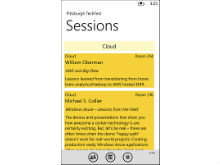

Windows Mobile Developer2010 - 2013

AccuWeather.com

Developing Windows 8 and Windows Phone apps. Managing software requirements, administering source control repositories, and configuring and maintaining build machines.

ASP.NET Web Developer2007-2010

Sikorsky Global Helicopters

Create and maintain web applications that improve existing business processes supporting Lean manufacturing using MS SQL Server, MS Access, ASP.NET and Microsoft Excel. Provide ad-hoc data analysis and continual improvement of IT process and service. Participated in SAP ERP implementation.

Programmer2004-2006

LC Consulting Services

Created and administered classic ASP websites driven by MySQL and MS Access databases. Designed, tested, and maintained software for engineering applications. Produced MFC applications, libraries, and websites.

Continuing Education

MOOC Programs

Coursera

Data analysis in R, Machine Learning, Mobile Robot Control Systems

Information Technology Management

Elmira College

Courses in Project Management, Leadership, IT Management

Spanish

Corning Community College

A semester of study (for fun!) courses in Spanish, ASL, Mandarin Chinese, Guitar, Percussion, General Music

Language, Music

Monroe Community College

A semester of study (for fun!) courses in Spanish, ASL, Mandarin Chinese, Guitar, Percussion, General Music

Education

B.S. Computer Science

Union College

Graduated Cum Laude with Psychology Minor.

About to Hatch

After a long time pondering the electrical system I decided that I would be fine using just a flashlight and that the more pressing issue was the leaking. I can't take the trailer anywhere with water coming in.

The trailer has been coated with what I think is asphalt sealer for waterproofing. While this might work more-or-less, the shelf was installed with gaps for water to seep into and there is a seam at the edge of the roof where water is channeled into. I want a hatch to keep the rain out and make this look like a teardrop. There are many hatch designs, but I found simple instructions for making a hatch and used them.

First, I took off the plywood of the aft bulkhead to open up the space between the galley and the cabin and see what kind of surface I had to work with. The roof is 1/4" plywood and is poor shape so I intend to replace it. The mounting surface is a 2"x4" and its solid.

I used cardboard to trace the outline of my side wall and took the templates and the plywood from the the old galley shelf to my parents house. My dad let me borrow his scroll saw to cut the frame.

Then I bought some 2"x2"s for the ribs and screwed together the frame seated in the back of the trailer to check my clearances.

The next day I went to the hardware store for some plywood sheets for the skin. I strapped the plywood and a sheet of insulation to the back of my baja with a bunch of straps and not too much trouble and brought it home.

I screwed the skin to the ribs and it bent pretty easily. There are some gaps that needed a some clamps which my dad loaned to me.

Now, with the hatch where it belongs this trailer look like a teardrop.

As for waterproofing, I have silicone caulk that I will fill the seams, gaps, and screw holes with to make sure they keep water out. Sealing the wood is a tough call, because I know Clear Polyurethane Epoxy CPES is effective and expensive, while Mineral Spirits & Polyurethane Varnish is cheap and promises to be adequate from what I read on tntt.com. Since I don't have the money to splurge, I'm going to go cheap and cross my fingers.

I ordered a Hurricane Hinge to attach the hatch and keep out water since they are so commonly used. I've been thinking to cheaply add edge trim by cutting 1"x2"s or by finding some cheap aluminum flashing. I'll add a hatch seal to keep out the weather and a latch to keep the hatch closed.